DIA Filler:

The key to realizing comprehensive

resin composite material solutions

The potential of DIA Filler,

a high performance filler developed through industry–academia collaboration

DIA Filler, with its innovative powder properties,

enhances functionality in components when compounded with resin composite material, thereby contributing to industrial decarbonization.

It also expands formulation flexibility and enables the realization of monomaterial designs.

The potential of DIA Filler,

a high performance filler developed through industry–academia collaboration

Achieving both high rigidity and light weight.

For example, DIA Filler enables automobile bodies to achieve the high rigidity required while significantly reducing weight. This feature makes it an essential solution for the development of mobility systems utilizing heavy batteries, supporting their evolution.

The potential of DIA Filler,

a high performance filler developed through industry–academia collaboration

Replacing all parts with resin composite material to reduce recycling costs.

DIA Filler allows resin composite material to be tailored to various levels of hardness and heat resistance. By replacing all interior automotive parts with resin composite material and unifying materials into monomaterial designs, it helps manufacturers reduce recycling costs and advance decarbonization.

The potential of DIA Filler,

a high performance filler developed through industry–academia collaboration

Realizing a circular economy that protects nature.

DIA Filler promotes the rebirth of resin composite material. Beyond automotive applications, it enables housings for PCs and devices to be reborn into entirely different products. Through rigidity adjustment, applications can even extend to surfboards, baseball bats, and many other fields. While preserving nature, DIA Filler accelerates material transformation and aims to realize a true circular economy.

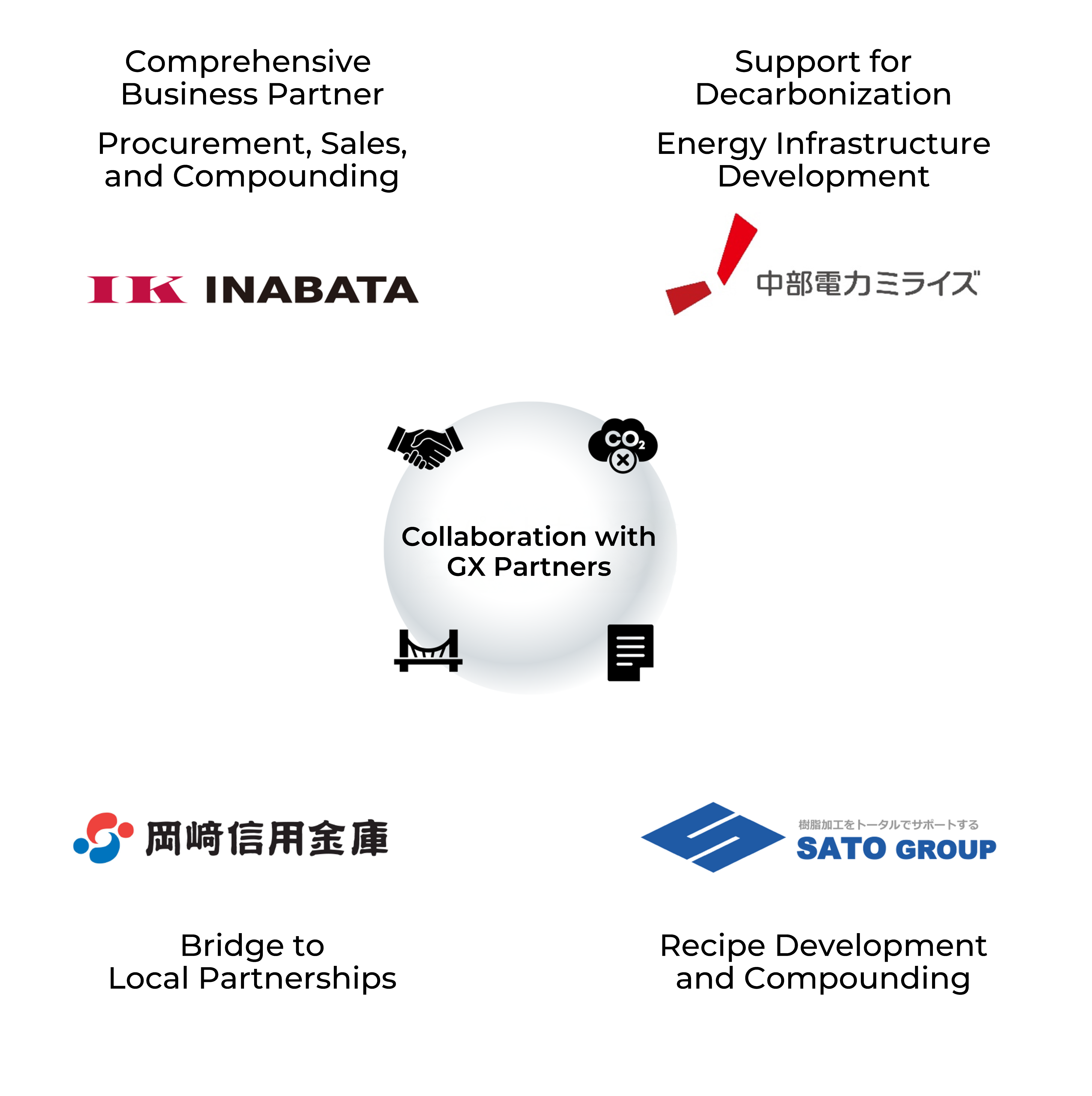

GX MINERALS is a company dedicated to creating Green Materials that connect to the future and driving GX (Green Transformation). Centered on the high performance filler “DIA,” developed through industry–academia–government collaboration, we provide products that achieve both decarbonization and enhanced functionality of resin composite materials. In commercializing our business, we partner with Inabata & Co., Ltd., Chubu Electric Power Miraiz Company, SATO GROUP, and The Okazaki Shinkin Bank to promote GX from manufacturing to sales.

- Company Name

- GX MINERALS INC.

- Founded

- May 16, 2023

- Representative

- President & CEO: Takao Ikeda

- Business Activities

- Development, manufacturing, and sales of high performance fillers that drive GX, as well as development, manufacturing, and sales of resin composite materials incorporating these fillers

- Headquarters & Facilities

-

Headquarters:Tonobashi Building 1F, 2-36 Kosei-dori Minami, Okazaki City, Aichi Prefecture

Factory:39-29 Onizuka, Uramachi, Tahara City, Aichi Prefecture (Production scheduled to begin in January 2026)

GX Promotion Partner Companies

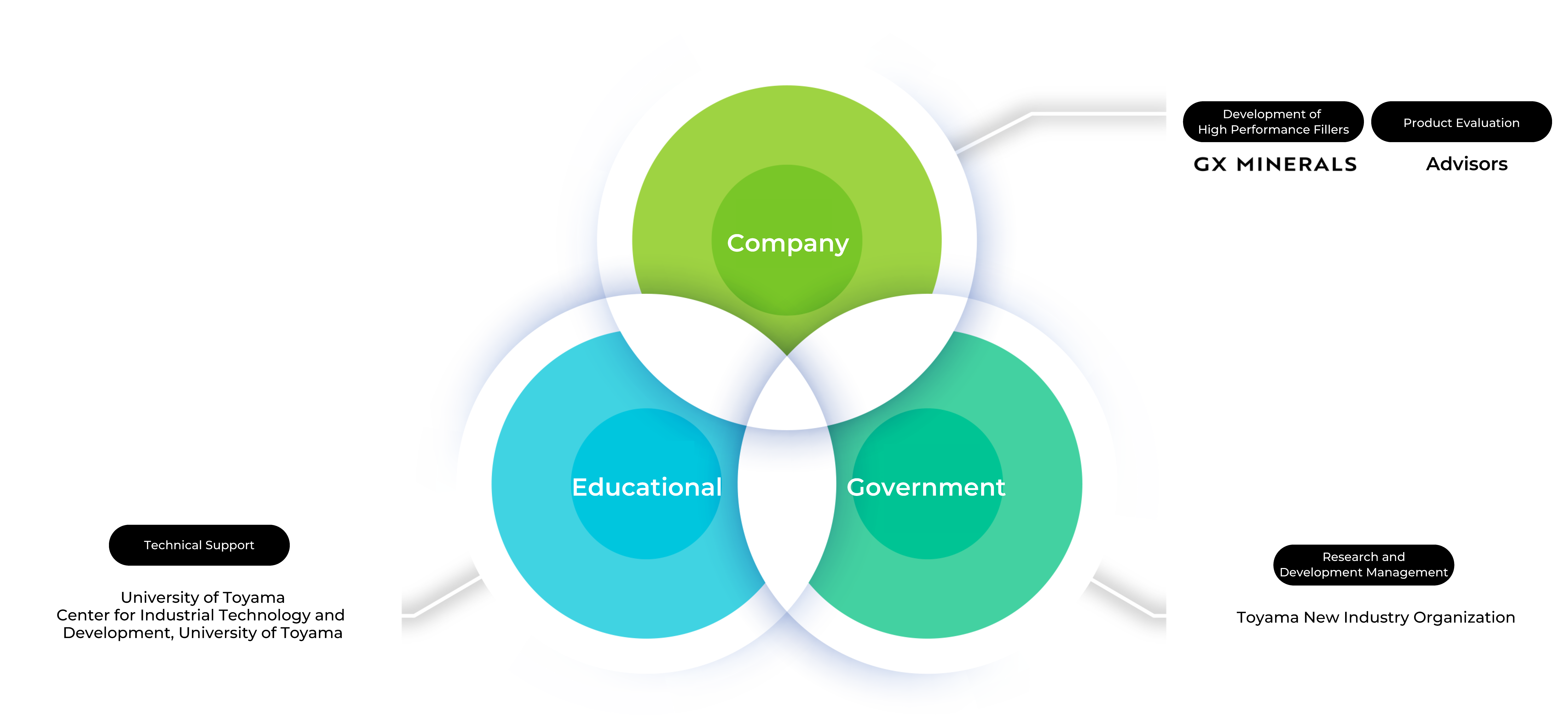

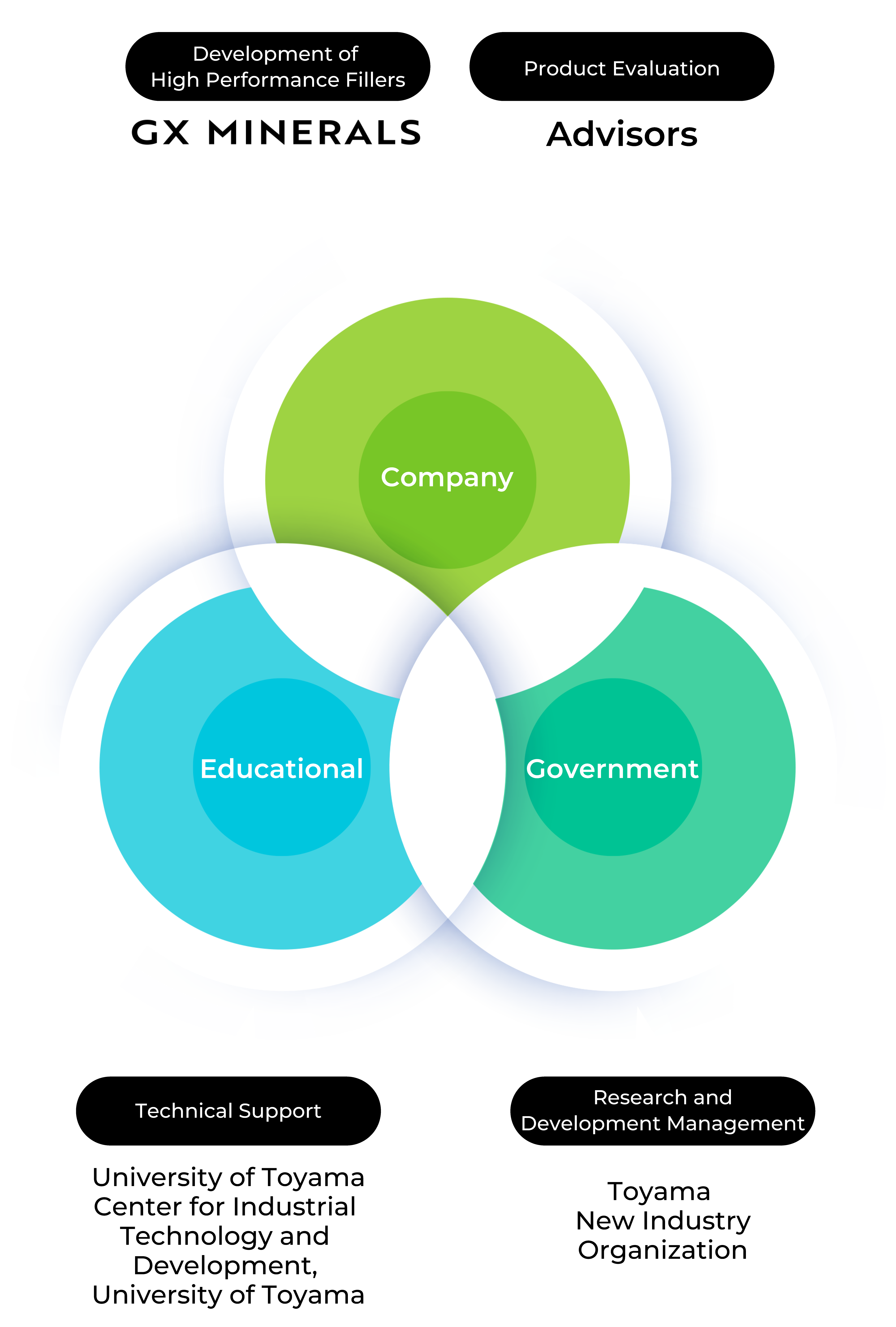

Industry–Academia Collaboration Initiatives

Product Development through Industry–Academia–Government Collaboration

2021 Strategic Core Technology Advancement Project by the Small and Medium Enterprise Agency, Ministry of Economy, Trade and Industry